Zepler Institute

State of the art cleanroom facilities at the Zepler Institute

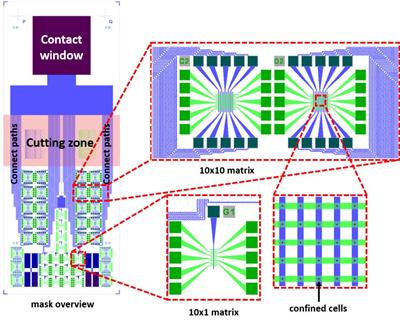

The Zepler Institute provides state-of-the-art facilities for design and fabrication of nanodevices across the breadth of the ADEPT programme. ADEPT team members have access to the clean room facilities

Future production of electrically contacted individual devices with feature sizes smaller than those currently produced by top-down techniques will require controlled bottom-up methods. The Damascene process pioneered by IBM and used to electrodeposit copper interconnects on silicon chips has been essential to the progress of VLSI to its current level. This process is fully integrated into microfabrication. Electrodeposition can produce very high purity materials, e.g. epitaxial magnetic films with a quality equal to those prepared by molecular beam epitaxy. Single and multi-component devices can be deposited into track etch structures or anodic alumina membranes with pores >30 nm using water or ionic liquids. However, much of the state of the art in electrodeposition into very small features for nanodevice fabrication lies in our work.

.jpg_SIA_JPG_fit_to_width_INLINE.jpg)

State of the art cleanroom facilities at the Zepler Institute

The Sustainable Electronic Technologies research group is part of Electronics and Computer Science at the University of Southampton