Research project: Micromechanistic analysis of damage evolution in aerospace and automotive materials - Dormant - Dormant

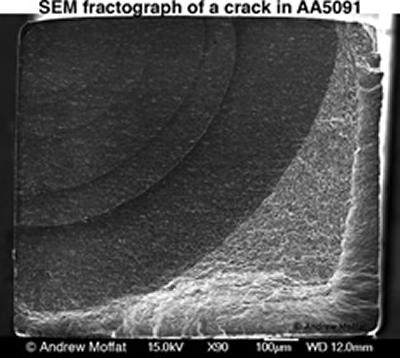

To improve lifing methods in structural materials a thorough understanding of the micromechanisms of damage is required in order to develop physically meaningful modelling approaches. High resolution X-ray computed tomography (X-ray CT) is a 3D imaging method that has been used to monitor the mechanisms of fatigue and tensile damage in aerospace and automotive materials such as composites and Al-alloys, where accurate lifing of components is essential.