Solutions for make-to-order companies

Production planning and control is an enduring challenge for manufacturers of high-value/high-variety/low-volume products, such as make-to-order companies. Many leading software packages are not designed for this environment, but for high-volume, low-variety flow shops. Workload control (WLC) is optimised for SMEs to achieve best manufacturing practice, enhancing their competitive advantages as suppliers of bigger manufacturing companies.

Technological advantages

- Designed for SMEs

- Uses lean manufacturing principles where full implementation is not possible

- Quotation to dispatch

- Reliable delivery performance

- Realistic and competitive lead times

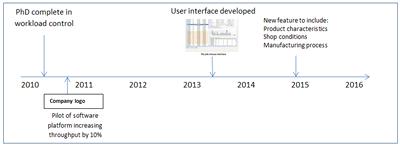

Technology roadmap

This work began in 1989, with a PhD study that resulted in the development of the WLC concept to apply lean thinking to make-to-order production systems, enabling streamlined production flows and controlled lead times. The WLC concept has been applied to a number of companies in the UK/EU, including PDS Engineering (a small precision engineering company in North West England), along with the development of the WLC software system. The use of the WLC software has been demonstrated, with significant improvements in customer quotation management, delivery performance, product quality, shopfloor transparency, understanding of capacity constraints, and the ability to meet customer audits. Improvement opportunities were identified and. in 2011 version 4.0 of the WLC software system was developed in C# and supported by a MySQL database. Future developments will address different (company-specific) product characteristics, shop conditions and manufacturing processes.

Collaboration opportunity

Potential collaborations can range from an MSc project (costing around £800 for travel and a stipend), one-hit consultancy, typically for three months and in the order of £15,000 through to customised software systems to address specific production issues, typically taking the form of a PhD over three years at (£12,500/year).

If you would like to know more, please contact aerospace@southampton.ac.uk