Tin sulphide is currently being developed as a friction material for automobile brake pads. Conventionally, antimony sulphide has been used as brake pad friction material but recently, especially in Europe and the US, antimony products are being used less frequently because they are suspected of causing environmental pollution. Development of tin sulphide as an alternative to antimony sulphide is currently in progress (ref: Nippon Chemical Industrial).

A number of patents have disclosed use of the individual tin sulphides, tin(II) sulphide (SnS) and tin(IV) sulphide (SnS2), and these existing tin sulphide systems have already captured a significant share of the friction modifier market, especially in Europe. However, their relatively high price compared to antimony trisulphide has restricted their use. The Optoelectronics Research Centre (ORC) has developed a preliminary process based on atmospheric pressure CVD for the deposition of tin sulphide of varying stoichiometry.

Technological advantages of CVD of tin sulphide for anti-friction coatings

- Lower cost process at atmospheric pressure with minimal waste

- Use of inexpensive precursors

Technology Roadmap

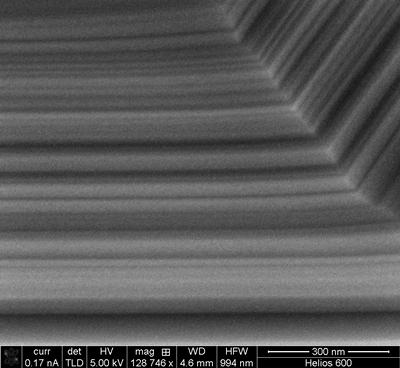

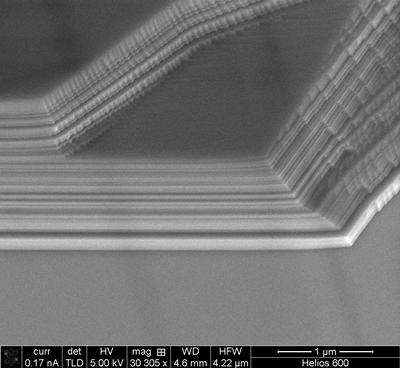

- Process developed and demonstration of multilayer films

Collaboration opportunity

We are interested in working with partners to define application requirements, and with those with the ability to scale up the process to commercial manufacturing volumes.

If you would like to know more then please contact Professor Dan Hewak dh@orc.soton.ac.uk