Next-generation nanomaterials and devices

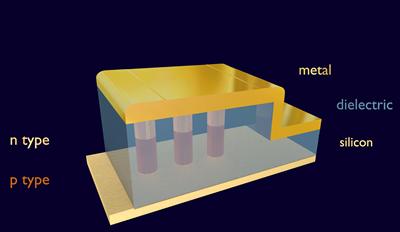

Current methods of producing nanoscale devices such as transistors are rapidly approaching their fundamental physical limit. To continue the drive toward smaller, faster and more powerful devices requires a completely new manufacturing technique. SuperCritical Fluid ElectroDeposition (SCFED) integrates proven technologies to offer a disruptive, scalable approach to depositing metals and semiconductors at the extreme (sub-10 nm) scale.

SCFED offers a scalable route to manufacturing high-quality nanostructured materials that can be exploited in a wide range of civil, defence and security applications: for example, sensors and ultra-high-efficiency thermoelectric devices for energy harvesting.

Technological advantages of SCFED

- A scalable approach for depositing high-quality nanostructured materials sub-10nm

- Proven for both metal and semiconductor nanostructures

- A technique for depositing high-efficiency thermoelectric materials

Technology roadmap

The SCFED project uses proof-of-concept and developmental test reactors to produce ever-smaller and higher-quality nanostructures. It also has access to the latest characterisation technologies for demonstrating device performance. SCFED nanostructured materials can be tailored for a broad range of applications and the multidisciplinary collaboration is uniquely positioned to develop these to meet the requirements of industrial partners.

2009-2011: Method: proof-of-concept study

2010: First demonstration

2011: Awarded EPSRC programme grant: SCFED project

2011-2016: SCFED development and application demonstrators

Collaboration opportunity

The SCFED project (www.scfed.southampton.ac.uk) combines expertise in different areas of chemistry and physics, and has access to advanced facilities. SCFED nanostructured materials can be tailored for specific applications and present opportunities for accessing the team’s capabilities.

If you would like to know more, please contact Professor Philip Bartlett p.n.bartlett@southampton.ac.uk