Innovative environmental investment in Chemistry to be replicated

An investment in Chemistry has been so successful at reducing the University’s electricity usage that similar changes are to be introduced in a second building.

When Building 30 was constructed in 2000, it was fitted with a state-of-the-art fume cupboard extractor system. The system helps protect students and researchers from harmful fumes – ensuring that they are safely extracted.

While the existing system was cutting edge, the fume extraction process was very energy intensive, and for much of the day it ran at a higher rate of exhaust than was actually necessary – especially if fume cupboards were left open overnight accidentally.

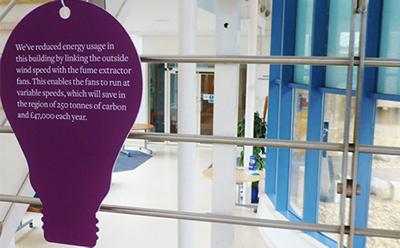

In 2012, an innovative project was initiated to link the extraction fans with the outside wind speed, so that the stronger the wind blew outside, the slower the fan speed necessary to safely extract the fumes.

The University of Southampton was the first institution in the country to utilise this technology, and the process included developing a physical model of the campus which was tested in a wind tunnel.

In the first year of operation, the project saved £47,000 worth of electricity – enough to recoup the initial investment in just 2.5 years.

Having been so successful, this approach will now be replicated in another Chemistry building, Building 29. It is expected that the changes will be implemented by October 2016.

Led by colleagues in Chemistry and Estates and Facilities, both projects have been supported by the University’s Carbon Management Fund – a £4m investment in ideas that will reduce the institution’s carbon emissions and improve the sustainability of our campuses.

Find out more on Facebook and Twitter, or email (sustainability@soton.ac.uk) the Sustainability team.