For post combustion capture of CO2, Absorption Reactors are the most widely applied method. They mix the exhaust gases with a solution that absorbs and removes the CO2 and there are several pilot plants in operation. However, research continues to improve various parameters of the process such as type of solvent, operating conditions and structured packing designs which are used to expose the CO2 to the solution. Research done by Dr Lindsay-Marie Armstrong and her group has focused on improving the designs of the structured packing. They have used computational multiphase models to understand the distribution of the solution on packing sheets and have developed structural designs that maximise the absorption process.

Modifying the sheets too much can significantly affect the pressure drop which incurs further operational expense to overcome. The group tackles this problem at:

- The micro-scale - understanding near-plate flow characteristics and developing flow control measures that can maximise the surface area of the solution on individual sheets.

- The meso-scale - modifying plate alignment and orientation to minimise the pressure drop factors between the sheets.

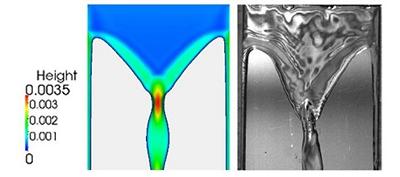

The image on the left shows computational film thickness at Re = 134 and plate inclination of 60o compared to an experimental case at Re = 162 from the literature (taken from Hoffman et al., Chem. Eng. Res. and Des., 84(A2): 147–154).

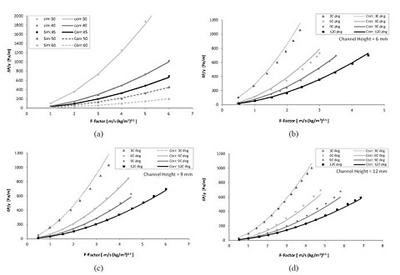

The one on the right illustrates pressure drop predictions for various structured packing channel dimensions and sheet inclination angles using a develop pressure drop correlation.

Links to external websites

The University cannot accept responsibility for external websites.

Industrial capture

Carbon capture takes place in Carbon Capture and Storage (CCS) plants which are typically situated next to coal or gas power stations which are producing the carbon dioxide to be captured. A ‘capture-ready’ power station is one that has been designed and built for subsequent retrofitting with CCS technology. Retrofitting requires space to be set aside next to the power station, as well as an identified pipeline route to transport the captured CO2 to a suitable storage formation.

Global CCS

There are eight operational CCS plants including In Salah, in central Algeria: operational since 2004 and injecting over 1 millions tonnes of CO2 annually; Sleipner, in the North Sea, about 160 miles west of Stavanger, Norway: operational since 1996 and injecting over 1 million tonnes of CO2 annually; Shute Creek Gas Processing Facility in Wyoming, United States, operational since 1986 and capturing 7 million tonnesof CO2 annually; and the Great Plains Synfuels and Weyburn-Midale Project in Saskatchewan, Canada: operational since 2000 and capturing 3 million tonnes of CO2 annually.

The way forward for CCS in the UK

In November 2015, the Government announced that, following the Chancellor's Autumn Statement, the £1 billion funding which had been the ring-fenced capital budget for the Carbon Capture and Storage (CCS) Competition was no longer available. This decision means that CCS research in the UK, which was poised to take a significant step cannot now proceed. The government said it would engage closely with the the Shell Peterhead project and the Capture Power White Rose project, who were the preferred bidders, on the implications of this decision for them.