Failure of rail axle bearings: saving train passengers time and money

Key details of this case study:

Summary: Our research analysing failed rail-axle-bearings on passenger trains is leading to a diagnostic link for monitoring their condition, saving industry a potential 30% in maintenance and improving safety.

Status: Ongoing

Key staff: Dr Ilaria Corni and Dr Nicola Symonds

Explore this case study:

The challenge

Rail vehicle axle-bearing failure is a serious issue which often results in service delays and potential fire and derailment, with obvious risks to life.

Southeastern Railway company has fitted more than 5,000 bearing sensors to its Electrostar fleet. These sensors provide real-time condition monitoring and are able to detect rail axle-bearing degradation. In an on-going project funded by the sensor manufacturer, Perpetuum Ltd, our researchers are forensically examining ex-situ rail axle bearings with recorded vibration histories.

Our challenge is two-fold: to identify and characterise the damage on these bearings; and to find a relationship between rail axle-bearing vibration data and physical damage to the bearing’s surface. Armed with this knowledge, we will be able provide a diagnostic link for condition monitoring, improving the current damage detector system.

What we did

Underpinning our research is failure investigations and Tribology – the science and engineering of interacting surfaces in relative motion, including the study and application of the principles of friction, lubrication and wear. Our scientists relied on their expertise in this area to address the project’s challenges.

Through extensive fractography, our researchers confirmed that the bearing surfaces were damaged via a mechanism called Rolling Contact Fatigue (RCF).

These fractographic examinations included surface profilometry, optical microscopy, scanning electron microscopy and computer tomography. We also examined historical vibration data in conjunction with the measurable parameters of the physical damage observed.

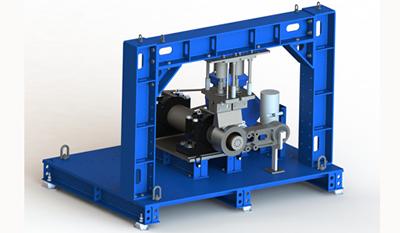

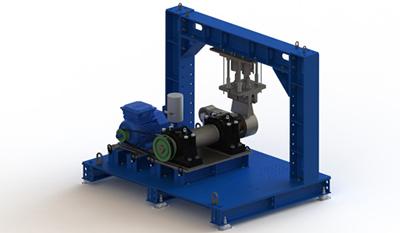

Initial indications of a relationship were found when we examined many example bearings removed from service. However, the next stage of the work will allow us to create our own damaged bearings with our new full-scale rail-axle bearing test rig, provided by Perpetuum and housed at the University.

Funding

This research has been funded by Perpetuum Ltd, the IAA-KTS funding from the Engineering and Physical Sciences Research Council and by WARNTRAK 672265 (Horizon 2020-SMEINST-2-2014).

We were awarded £1.1M by Innovate UK’s Accelerating Innovation in Rail competition to design and build a four-point rotating bend rig to simulate a rail axle in service. This award was achieved in collaboration with Perpetuum and TWI.

Our impact

By using condition monitoring, over 30% (£3 billion p.a.) could be saved worldwide just for passenger train bogie maintenance, with the added benefit of major improvements in safety and reliability.

Perpetuum's Energy Harvester powered wireless sensor systems have been successfully installed for on-board and real-time condition monitoring of bearings and wheels. This project itself will develop the capability of the damage detection system to become diagnostic, and eventually prognostic. Our work will also impact other sectors as rolling element bearings are widely used in helicopters, wind turbines, engines and power plants, etc.

A recent development of this work has led to the design, build and assembly of a full-scale rail-axle bearing test rig, to mimic the loads and speeds of a commuter train on the subject bearing. This brand new and unique academic facility will provide our scientists with the information to further investigate the degradation of large rolling element bearings.

The facilities we used

We used the following facilities within the University - Multidisciplinary, Multiscale, Microtomographic Volume Imaging Centre; Full Scale Bearing Test Rig.

Find out more about the Engineering and Environment Faculty's many world class facilities.

We are grateful to Southeastern Railways for their access and support during this project.

Partners we worked with

Our research partners in this project are Perpetuum and Southeastern Railways.

This research project forms part of the University's nC2 Enterprise Consultancy Unit.

Related media

Related Staff Member

Related Staff Member

Links to external websites

The University cannot accept responsibility for external websites.

Other University of Southampton sites

You might also be interested in

nC2 - The University's Engineering consultancy

The nC² business unit within the University provides high-quality material analysis, failure examinations and characterisation for many industrial sectors.

Other Manufacturing and Materials case studies

Learn more about the research we are undertaking in these areas.

Postgraduate Opportunities

Explore our postgraduate research degrees.

Media Enquiries

Make a media enquiry about this case study