Quiet skies: Reducing the noise of Rolls-Royce jet engines

For over 25 years the University of Southampton has been working with Rolls-Royce on fundamental research into jet engine noise. This long-standing partnership has contributed to a significant reduction in the noise levels of Rolls-Royce jet engines. For example, the Trent XWB engine first introduced in 2014 is around 14dB quieter (cumulative for the 3 certification points) than the Trent 800 engine produced in 1997.

Technology centre

The University of Southampton’s Institute of Sound and Vibration Research (ISVR) hosts the only Rolls-Royce University Technology Centre (UTC) in Gas Turbine Noise, and is one of around 30 UTCs worldwide partnered by Rolls Royce.

The level of integration and trust between the two organisations has enabled the University to become an integral part of the Rolls Royce research team, advising on its in-service technology and developing joint strategies for tackling important issues related to the noise of future jet engines.

Opportunity

Nick Humphreys, Associate Fellow, Rolls-Royce, says: “Rolls-Royce has always tried to minimise the environmental impact of its products, including noise signature, and tough future environmental targets are resulting in the need for ever quieter and more efficient products. This is opening up a huge range of opportunities for the aero engine industry and forcing a radical rethink of future aircraft design. But new design concepts, such as integrated and distributed propulsors, and the introduction of electric and hybrid technology, can lead to complex acoustic interactions.”

Alec Wilson, Professor in Computational Aeroacoustics at the University of Southampton, adds: “These advanced design concepts open up new opportunities for noise reduction, but also have the potential to introduce new sources of noise that have to be modelled and controlled.

“Our work doesn’t stop with modelling individual noise sources, however the most important question is what people hear on the ground, which means we have to combine a physical understanding of individual noise sources with operational factors related to different types of aircraft, and the way they fly during take-off and landing.”

Working in partnership

Our 30-strong Southampton UTC team, made up of academics, consultants, research fellows and PhD students, develops state-of-the-art methods and tools to explore the installed effects of the engines in different designs, such as blended wing-body aircraft. This in turn enables the company to assess and to minimise the noise footprint of future engine/aircraft configurations.

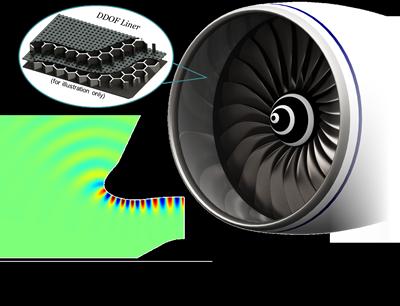

The Rolls-Royce UltraFan® concept provides a step-change in technology and increase in engine bypass ratio to provide further fuel efficiency and significant reductions in both CO2 and noise beyond the benefits of nearer term products. The Southampton team is working with Rolls-Royce to accurately model the key noise sources including the new fan system (a larger diameter fan coupled with the world’s most advanced gearbox) which will enable the benefits to be optimised during the design cycle.

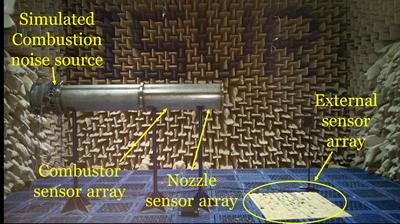

Another key area led by the Southampton team is the design of advanced microphone arrays for use in rig and engine tests. Measurements from these arrays are used to track and identify different sources of engine noise. One of the key challenges is developing this technology for use in an indoor engine test cell where the measurements can be contaminated by reflections from the cell walls and equipment. Detailed understanding of the noise sources through the combination of methods and measurements enables improved optimisation of environmental emissions, including noise, for the final product.

Future challenge

Air transport around the world is growing, and this growth is essential for global business. The challenge for the industry is to absorb this growth whilst still reducing overall noise levels around airports.

The UTC, working together with Rolls-Royce and the wider industry, will provide the technology and tools to make this a reality.