Overview

Projects

Water droplet impingement experiments

Specifications

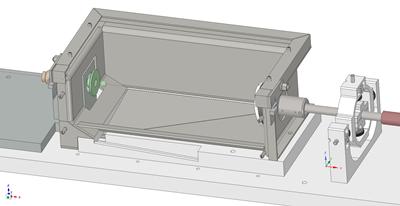

The rig is a pneumatic powered system from the air-lines in the laboratory. The line connects to a valve and pressure gauge that controls the pressure in an accumulator. The accumulator stores a volume of air awaiting release by a very-fast acting valve that is electronically opened by a foot pedal. This is connected to a smooth-bored barrel, manufactured by a gunsmith such that is makes a near gas-tight seal with the projectile. The barrel is mount on two gimbal arrangements allowing elevation and direction adjustments. It also has two light gate mount near the muzzle to record the exit velocity.

The projectile is a 9 mm diameter ball, usually unhardened as they tend to shatter, and it is loaded to the back of the barrel and in operation is fired by the sudden release of the gas in the accumulator into the test chamber, which is designed to securely contain the energy of the project. It has two sheet of Perspex that are 10 mm thick, these allow visualisation of the impact event (potential with a high speed camera). The sheets are removable for installation of a new sample and removal of the projectile and previous sample. The sheets have micro-switches that prevent accidental firing if they are not in place.

The sample is mounted on the end of a striker bar, that is mounted on vibration isolation mounts. At the end of the striker bar is mounted an accelerator to record the pressure waves from the impact.

This rig was originally designed for the testing of high-strain resistant materials and the ability of auxetic material to absorb strain. More recent work has adapted the rig to be able to perform water droplet impingement in a fundamental study on water droplet erosion, this is shown in more detail in another tab.

Projects:

- Impact and erosion resistant materials - 3D printing of auxetic foams - Auxetic materials are extremely attractive as engineering materials due to their enhanced mechanical properties. To date, auxetic performance has been documented at a range of length scales, from materials including polymers, metals, ceramics, composites, laminates, and fibres. This work has fabricated repeatable auxetic foams produced using a 3D printing technology (additive manufacturing).

- Water droplet erosion of aeroengine fan blades: the importance of form.

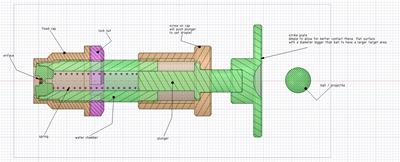

The rig has been adapted by Safire and Associates for a PhD student project. the adaption allowed the removal of the striker bar replacing it with a plunger system. The plunger was designed to be impacted by the ball fired from the main barrel. The plunger pushes against a positioning spring and squeezes out a slug of water captured in the chamber through a specific nozzle. By change the ball's impact energy and the size of nozzle slug velocities of over 200 m/s have been recorded.

The other part for the adaption is the sample holder, which allows vertical and horizontal alignment of where the water slugs strikes.

The water slug shape, velocity and the impact on the surface are examined using a very-high speed camera, measuring up to 5 million frames per second. This requires significant amount of time to capture the desired duration, which can last just a few microseconds.

Rig Specifications:

| Attribute | Range/Value |

|---|---|

| Impact Velocities | x to y m/s |

| Projectile | Unhardened 9 mm diameter bearing ball |

| Firing mechanism | Pneumatic accumulator and high-speed valve |

| Velocity measurement: | Twin light gates |

| Measurements: |

Acceleration (accelerometer on bar) Ball velocity High-speed photography* |

* - an operational measurement, requires a high-speed camera