Research project: 3D Imaging Of The Tensile Failure Mechanisms Of Carbon Fibre Composites

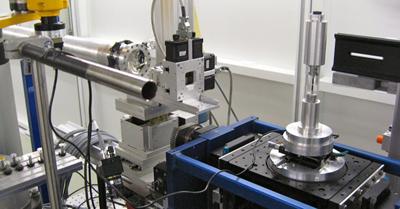

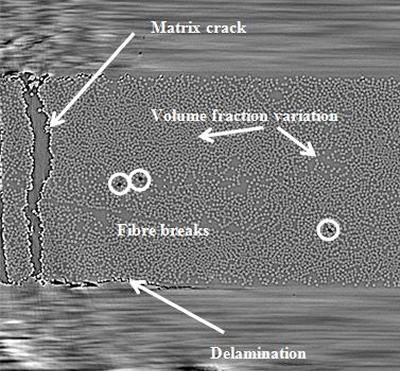

Synchrotron radiation computed tomography (SRCT) has been used to analyse and quantify the tensile failure mechanisms in carbon fibre/epoxy composites. Two specimen types are analysed – small, aerospace grade coupons, loaded in situ, and filament wound matchstick samples taken from incrementally loaded hoop-wound and scanned “post mortem”. The effects of fibre, matrix and interfacial properties on the initiation and accumulation of fibre breaks are analysed. Attention is focused on the formation of clusters of broken fibres, as the development of a critical size of interacting fibre breaks is believed to be the strength-defining failure event.