Research project: Early detection of contact distress for enhanced performance monitoring and predictive inspection of machines

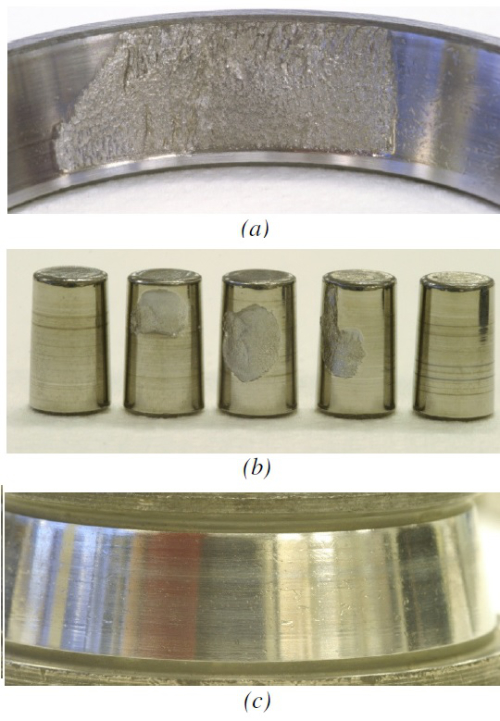

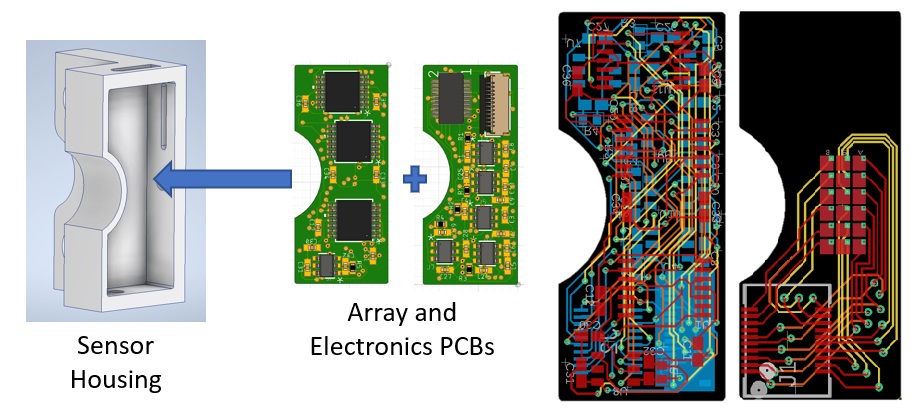

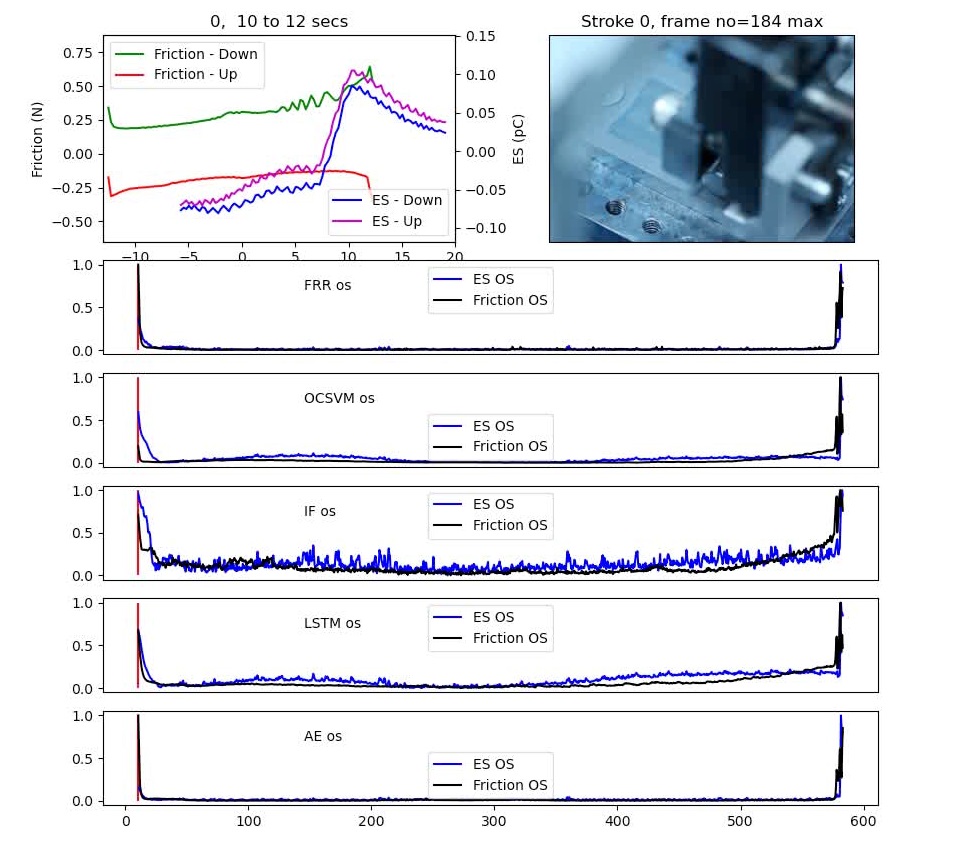

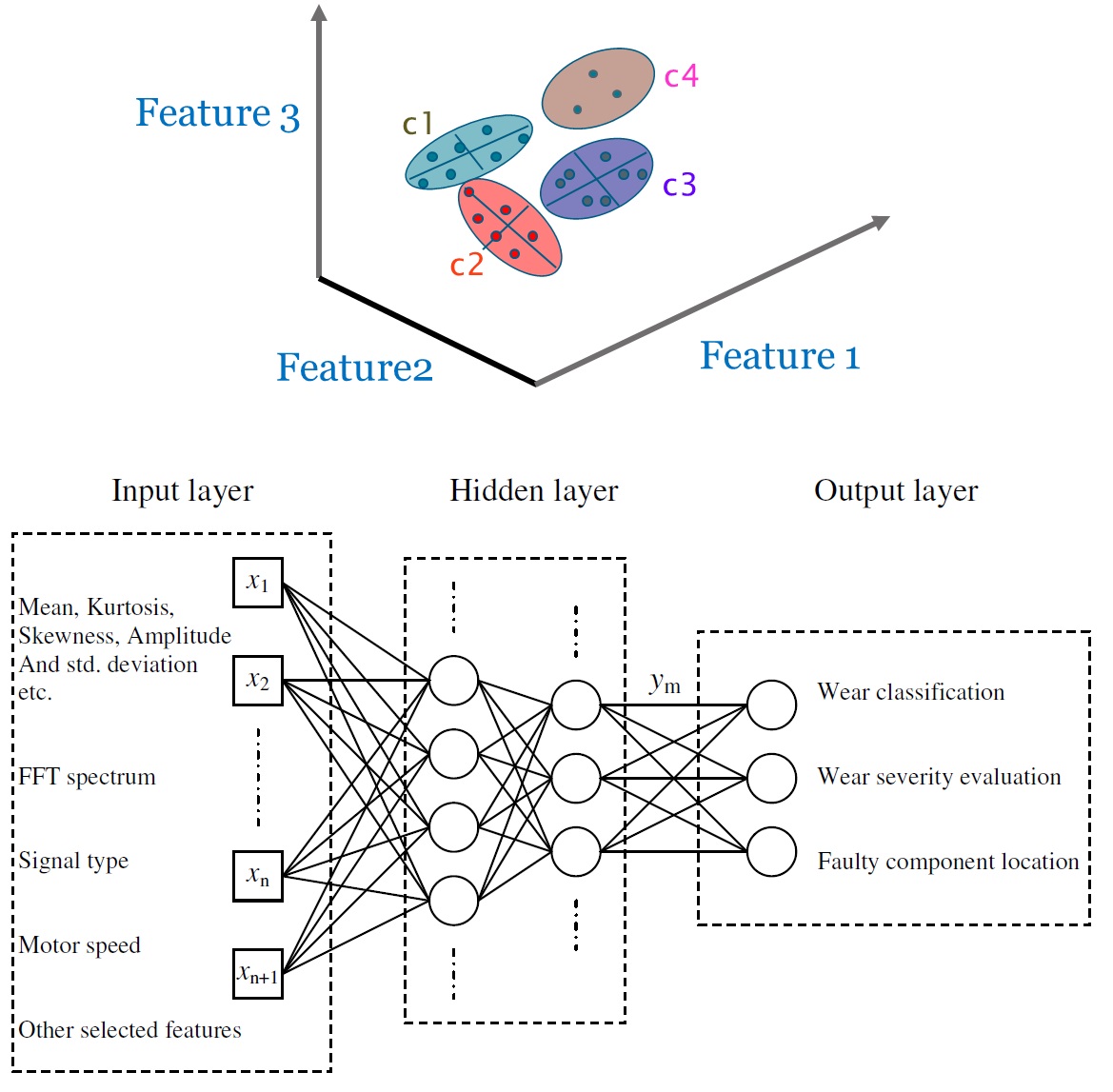

Monitoring the health of tribocontacts requires the study of friction, tribofilm integrity, and wear transitions. This project will miniaturise existing sensing technology, with embedded electronics to overcome signal to noise issues, and use arrayed sensors for augmented sensing, and machine learning.