Research project: Effect of surface defects on rolling contact fatigue of wheel/rail steels

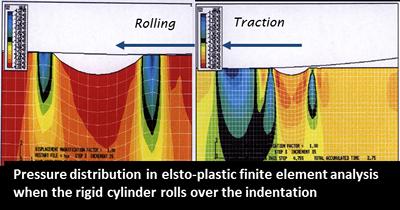

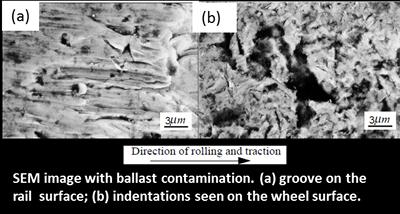

The mechanism of rolling contact fatigue is complex and many factors have to be considered. Surface roughness and the presence of surface defects are known to be important factors. The aim of this project is to investigate the effect of surface defects on rolling contact fatigue of wheel/rail steels by finite element analysis and using a twin-disc rolling-sliding test machine.