S. Chaudhuri1, J. Crump2, P.A.S Reed1, B.G Mellor1

1. Engineering Materials Group, Faculty of Engineering and the Environment, University of Southampton

2. TWI Ltd, Cambridge, UK

Background

Weld toe fatigue crack initiation is highly dependent on local geometrical imperfections such as inclusions, undercuts and cold-laps. These features are known to promote initiation early in the fatigue life however understanding their relative influence on propagation of early cracks into dominant cracks is still limited.

Role of µCT

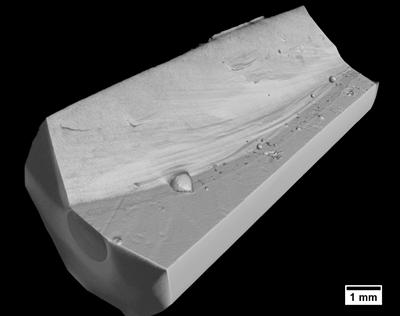

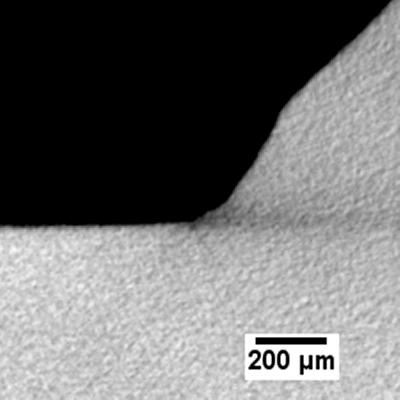

To understand further the influence of all parameters on the early fatigue life, micro-computed tomography (μ-CT) has been used (in combination with other measured parameters such as residual stress and hardness measurements) to fully characterise the welds. A novel work flow is being developed which creates 3D finite element models from the 3D μ-CT data. This enables a more accurate assessment of local weld toe stresses, which for the first time can be correlated, directly with the earliest stages of fatigue crack initiation. Results from this work would also inform us about the most critical weld toe geometries and how these control the fatigue regime in steel arc welded joints.

Figures

Figure 1 - Resolved weld toe geometry with X-Ray µ-CT

Figure 2 - Fatigue crack resolved by µ-CT for correlation with ACPD data

Acknowledgements

The authors would like to acknowledge the EPSRC and NSIRC for their funding and TWI Ltd staff for their assistance during the experimental work.

-