Rong Jiang1,2, Daniel J. Bull2, Angelos Evangelou2, Ian Sinclair2 and Philippa A.S. Reed2

1 College of Energy and Power Engineering, Nanjing University of Aeronautics and Astronautics, Nanjing, 210016, China

2 Department of Mechanical Engineering, Faculty of Engineering and the Environment, University of Southampton, Highfield, Southampton, SO17 1BJ, UK

Background

Nickel based single crystal (SX) superalloys are widely used in advanced turbine engines due to their excellent high temperature strength and exceptional resistance to fatigue, creep, oxidation and corrosion damage. During manufacturing, defects such as shrinkage pores and carbides are inherent within the material and are understood to have a strong influence on fatigue crack propagation depending on the size, density and distribution of these defects. Whilst it is clear that pores and carbides play a significant role in fatigue crack initiation, the mechanisms involved have not been fully captured experimentally. The focus of this research campaign is to provide a deeper understanding of the role of pores and carbides in strain localisation and fatigue crack initiation. This is achieved by linking the 3D microstructural features (obtained from X-ray computed tomography) to the full-field strain distribution obtained from digital image correlation studies on SEM images, capturing the chronology of events through interrupted fatigue tests. The obtained experimental data can be used to develop and validate future fatigue life prediction models

Role of Computed Tomography

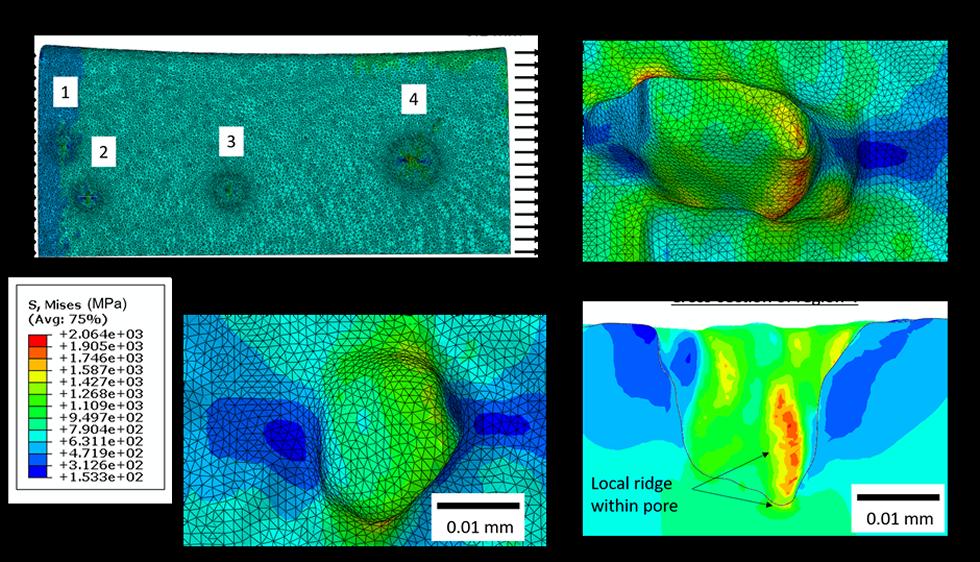

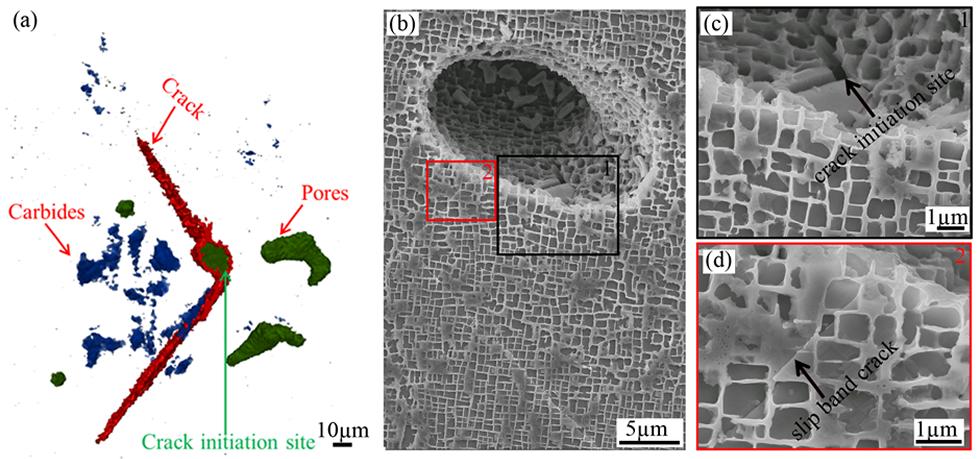

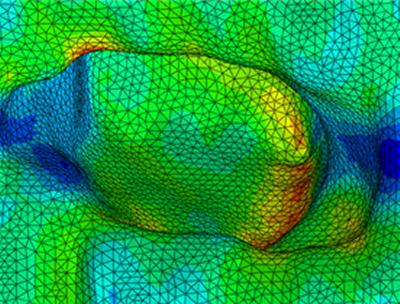

High resolution X-ray computed tomography (CT) was used to understand the 3D initiation and propagation of short cracks in an MD2 Nickel based superalloy and how it corresponds to material defects such as porosity. CT was also used to quantify the porosity and carbides (sizing and distribution) inherent within these material systems. To establish the role of crack initiation from porosity, a 3D mesh capturing the pore geometry was generated from CT data and used to create a finite element model of the stress distribution around the pores when the specimen was subjected to a tensile load. A strong correspondence was found between the magnitude of stress concentration factors around porosity sites, and the initiation of cracks observed in the CT dataset. The key observation was the local geometry, in particular a “ridge” within the pore, which locally increased the stress concentration factor leading to the initiation of the crack. This highlights that crack initiation linked to stress concentrations from porosity is governed by complex geometrical features beyond simply the size and aspect ratio of the pore.

The results from X-ray computed tomography and image-based modelling were used to complement the strain accumulation observations made with digital image correlation undertaken on sequentially fatigued SEM images. In the digital image correlation data, the magnitude of strain accumulation was observed to be enhanced near pores with significant strain concentration factors.

CT Scans were undertaken at Mu-VIS using the XRadia VERSA scanner. Due to the high X-ray attenuating properties of Nickel superalloy material, a dog-bone specimen with a cross-section measuring ~0.7x0.7 mm at the narrowest point was required to improve X-ray transmission. X-ray CT scans achieved a 0.8 micron voxel size and ~0.8 x 0.8 x 0.8 mm field of view. Multiple CT scans were undertaken along the length of the specimen at the gauge region to increase the field of view.

Publication

Jiang, R., D. J. Bull, A. Evangelou, A. Harte, F. Pierron, I. Sinclair, M. Preuss, X. T. Hu, and P. A. S. Reed. "Strain accumulation and fatigue crack initiation at pores and carbides in a SX superalloy at room temperature." International Journal of Fatigue 114 (2018): 22-33.

Acknowledgements

The authors would like to thank Prof. Pascal Lava from KU Leuven for provision of the MatchID software. The EPSRC (Grant no: EP/M000710/1) is gratefully acknowledged for funding support. The authors also would like to thank Prof. Liguo Zhao at Loughborough University, Dr. Mark Hardy at Rolls-Royce, Dr. Matthew Lunt at Defence Science and Technology Laboratory and Prof. Scott Lockyer at Uniper Technologies Ltd for several useful discussions of the results presented in this paper. Prof. F. Pierron gratefully acknowledges support from the Royal Society and the Wolfson Foundation through a Royal Society Wolfson Research Merit Award

Figures

- Image-based modelling of the stress concentration around the surface pores. The mesh was generated from the geometry of the CT data using ScanIP Simpleware. The pore associated with crack initiation (region 4) shows the most significant stress concentration.

- (a) X-ray CT examination showing the 3D crack morphology at 55k cycles; (b) crack initiation at the bottom of the pore at 50k cycles; (c) and (d) close-up of crack initiation site and slip band crack in the regions highlighted in (b).