Optics and power delivery for IR applications

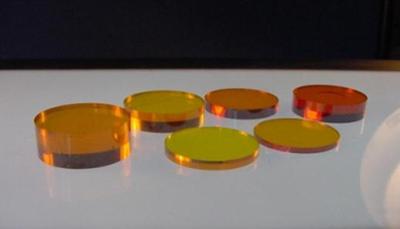

Since 1992, the University has been conducting research on a family of chalcogenide glasses, optimised for 1-6 micron applications. Our efforts at the Optoelectronics Research Centre (ORC) are now focused on developing a new family of IR glasses based on related compositions. These new glasses will transmit from 1-12 microns, covering the important CO2 laser wavelengths, thereby extending the transmission window. Our compositions are already proven to have higher thermal stability and hence a higher damage threshold. The fabrication of polished windows, lenses, microspheres and optical fibre is routine. Applications could include countermeasures, converting data transmission through air, for example positioning, spectroscopy and speciality manufacture.

Technological advantages

- Materials are based on a low-cost precursor in a process that is easily scaled.

- Materials operate in an important wavelength regime – CO2 lasers for power delivery, molecular fingerprint region for sensing and atmospheric transmission windows for aerospace and defence.

- Materials are easily processed into, for example, lenses; unlike conventional IR materials, they do not require individual diamond turning to process but can be mass produced by a hot pressing method.

Technology roadmap

1992: First demonstration of new IR glasses based on gallium, lanthanum and sulphur (GLS)

1993: Start three-year industry-funded programme to develop chalcogenide optical amplifiers (patent granted)

1995: World’s first demonstration of GLS optical fibre

1999: Complete five-year joint EPSRC/industrial programme to develop chalcogenide glass lasers

2002: First demonstration (EPSRC funded) of the synthesis of chalcogenides by chemical vapour deposition (patent granted)

2004: Commence work (EPSRC funded) on electronic memory applications of GLS (patent granted)

2010: Start five-year programme to improve glass purity and homogeneity through EPSRC Centre for Innovative Manufacturing in Photonics

2014: First demonstration of GLS thermoelectric device (EPSRC funded)

2014: Onwards: now partnering with UK industry manufacturers and users of infrared components and fibre

Collaboration opportunity

We are looking for partners with interests in infrared materials and commercial applications, of which there are a wide range (check EOI). We are also interested in working with partners with capabilities for improving and scaling up production processes.

If you would like to know more, please contact Professor Dan Hewak dh@orc.soton.ac.uk