3D mapping of material microstructures

The University of Southampton offers a dedicated centre for high-resolution computed tomography (CT), providing complete support for 3D X-ray imaging across the engineering, biomedical, environmental and archaeological sciences. The centre encompasses six highly complementary scanners. In 2005, EPSRC funded a project on the micromechanics of crack formation in CFRPs: since then, 10 PhD and postdoctoral projects have developed various aspects of composite measurement and performance, including manufacturing. The centre has received funding in excess of £4m in the form of a suite of world-class imaging and computing equipment, drawing on the expertise of over 40 academic staff across the university.

Technological advantages

- Comprehensive 3D mapping of materials structure/microstructure

- Non-destructive

- Imaged volumes up to 1.5 x 1 x 1m

- Resolutions down to ~200nm

- Specialising in composite structures

- World-class academic staff and operators

Example projects

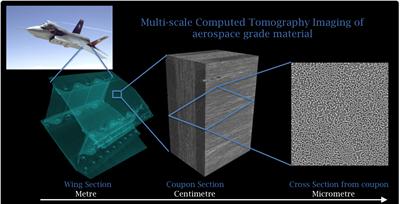

Multiscale computed tomography of aerospace composites

The multiscale capabilities of the microfocus CT at μ-VIS, in combination with synchrotron CT, enables three-dimensional data of the internal material structure in the metre range down to the sub-micrometre imaging of individual fibres. Wing component-scale parts (up to 2m max dimension) may be loaded in situ, enabling damage mechanisms in the material to be detected and segmented for analysis, and showing the progression of damage to failure.

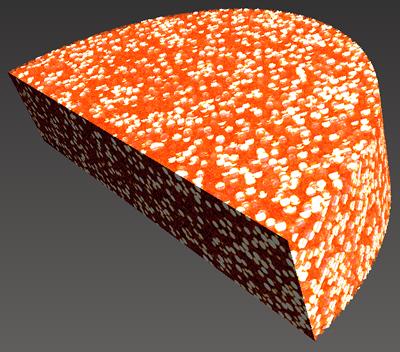

Online powder mixing technology and mixture characterisation

A mixing technique has been developed by Dr Shoufeng Yang at Southampton to produce repeatable homogeneous mixtures. During this project, a route was established to quantitatively assess the distribution of individual components in a mixture. Our custom CT scanner enabled the characterisation of a number of powder mixtures.

Collaboration opportunity

Short-term consultancy through to multiyear collaborative R&D, supporting process optimisation, model initialisation and validation, calibration/validation of complementary NDE/NDT methods (eg ultrasound, backscattered X-ray, acoustic emission).

If you would like to know more, please go to www.soton.ac.uk/muvis or email muvis@soton.ac.uk