Image-projection based laser processing

Laser machining of complex patterns with sub-micron resolution is an industrially relevant process technology. However, this approach can be slow if only a single scanning beam is used. Our novel approach involves the use of a digital micromirror device (technology used by the cinema projection industry) to spatially pattern our laser pulses in order to machine entire structures at once, and obtain orders-of-magnitude speed improvements. We can machine cm-sized complex structures, with sub-micron resolution, within minutes.

Our current research is to extend our machining technique to the manufacturing sector, in areas such as security, safety, anti-counterfeiting, MEMS and silicon photonics, biocompatible templates and more.

Technological advantages of image-projection based laser processing

- Fabrication of cm-sized structures, with sub-micron resolution, within minutes

- Applicable for subtractive (material removal) and additive (material addition) laser machining

- Technique can be used with many different laser conditions (e.g. wavelength, power)

- Patterning of identification codes on the surface of bulk diamond has recently been demonstrated

Technology Roadmap

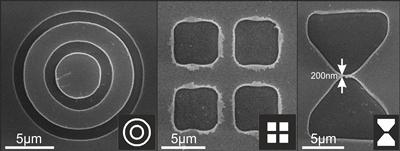

Subtractive machining via laser ablation (insets show the projected laser pattern) in thin films for a total machining time = 1 laser pulse

Applications include: thin-film ablation, component trimming, forensic-level security marking

Additive machining via laser polymerisation, resulting in formation of complex polymer structures on a surface using a single laser pulse

Applications include: bio-scaffolding fabrication, 3D waveguide and light-coupling structures

These approaches have been used for the fabrication of cm-sized objects on time-scale of minutes. A fully-automated prototype machining device, currently under construction, will be tested at several UK/EU commercial laser-machining companies during early 2015.

Collaboration opportunity

If you are interested in contract research opportunities, project partnerships, trial machining or would just like to learn more, please contact Dr Ben Mills (bm602@orc.soton.ac.uk) or Professor Rob Eason (rwe@orc.soton.ac.uk)

This work is funded under EPSRC grant numbers EP/L022230/1 and EP/J008052/1.

Other University of Southampton sites