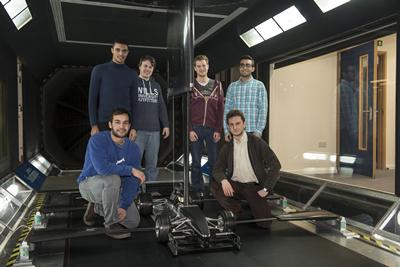

Testing a group design project in Southampton’s historic wind tunnel

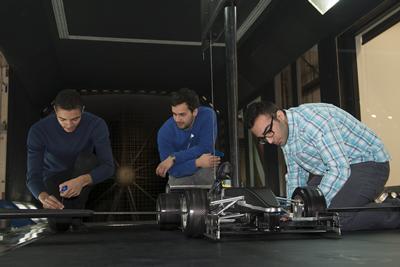

Final year engineering students have been testing out their work on a one third scale model of a hill climb racing car in the University of Southampton’s RJ Mitchell Wind Tunnel, aiming to improve its aerodynamic performance.

They had been given cutting-edge parts manufactured through a revolutionary 3D printing process by Williams F1 Team, thanks to links established by team member Arslan Ahmed who had worked at the Grove based company on a year’s placement.

The six month Group Design Project (GDP), undertaken by all Engineering undergraduates, tests their teamworking and project management, as well as engineering skills. Arslan and his colleagues Arjun Biswas, Daniel Scadding, Alex Norton, Marco Giovannelli and James Collins have been working on how to increase the car’s performance while in yaw and steered conditions, vital factors to improve cornering on the track, designing their own software to analyse the data and liaising with Williams over the exact specifications of the parts.

“We are fortunate in being able to use the RJ Mitchell Wind Tunnel for our project,” explains Arslan. “Not only is it a superb facility, it is steeped in history. Many F1 cars have been tested here and Adrian Newey, who’s now Chief Technical Officer at Red Bull Racing, actually used it for his final year project at Southampton.”

“The students are very professional and know what they want to achieve from their tests with us,” says Wind Tunnel Manager Dr David Marshall. “This hands-on experience is vital as they develop their skills as engineers.”

The team, supervised by legendary aerodynamics academic and expert Professor Xin Zhang, will be writing up their project over the next two months before presenting their work to senior academics.