‘Tesla of the Seas’ unveiled following tests at Southampton wind tunnel

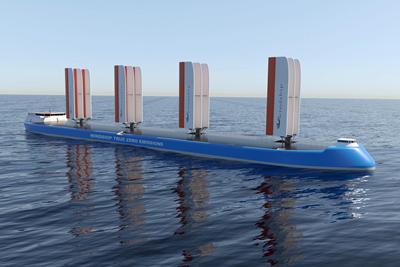

British firm Windship Technology has unveiled an innovative zero emission ship design based on a highly efficient triple-wing rig that exploits the power of the wind.

The eye-catching solution, known as the ‘Tesla of the Seas’, was extensively tested at the University of Southampton’s Wolfson Unit for Marine Technology and Industrial Aerodynamics.

Experts at the renowned engineering consultancy helped predict power and fuel saving performance, drawing upon data from scale model rig tests at the R.J. Mitchell Wind Tunnel.

Without significant mitigating action it is projected that the global shipping industry could account for almost a fifth of carbon emissions by 2050.

The Windship solution proposes three 35-metre high masts on the deck of a ship, each fitted with aerodynamic wings. The design provides significant thrust to allow for reductions in engine power that maximise fuel-saving and emissions reduction.

The company’s technical team have further developed a new diesel electric ship drive system that eliminates CO2, NOX, SOX and particulate matter to ‘True Zero’ whilst also incorporating large solar arrays, carbon capture, optimised hull shapes and specialised weather routing software.

Philip Wilson, formerly Professor of Ship Dynamics at the University of Southampton, says: “The holistic approach demonstrated in this solution whereby wind power, solar power and the reduction of harmful exhaust emissions to effectively zero, are all brought together, means that at last there is a design solution that the International Maritime Organisation can champion to achieve its requirements for ‘at least’ zero carbon shipping.”

The wind tunnel tested triple-wing rigs produce a driving force several multiples greater than single masted solutions of the same height and are stowable on deck to aid port navigation and cargo handling. The composite structure is borne out of technology and design from the wind turbine industry, ensuring reliability and longevity of greater than 25 years.

The ‘Tesla of the Seas’ is gathering momentum as regulators such as the International Maritime Organisation backed by the United Nations demand environmental and sustainable reform from the industry.

This month, Windship Technology announced the project’s latest step forward in a new partnership investment with DNV. The registrar and classification society will fully assess the whole-ship design with a view to classifying emission reductions, safety and operability.

Lars Carlsson, Director of Windship Technology, says: “Working with DNV is a major step towards proving true zero emission status. The clock is ticking and regulation will force a new approach for an industry that is traditionally hesitant to change. Shipping and oil companies are the only major industries still increasing their emissions and must change and think differently if it is to have any hope of reaching the emissions targets set out in law.”