Research project: NECOBAUT: iron-air redox flow battery

A new concept of metal-air battery for automotive application based on advanced nanomaterials.

A new concept of metal-air battery for automotive application based on advanced nanomaterials.

The aim of NECOBAUT Project is to develop a new concept of battery for automotive based on a new metal/air technology that overcomes the energy density limitation of the Li-ion battery used at present for Electrical Vehicles. Some metal/air cells were developed in the past, but did not give the demanded requirements for commercial use. Two decades of improvements in materials for electrodes, electrolytes and batteries and mainly in nanomaterials were helpful for developing a battery that should fulfill the requirements of the car industry. The technology that is developed in the project addresses mainly the design and manufacturing of both electrodes of the battery: the negative electrode composed by the selected metal, and the air cathode with the catalyst supported on a carbonaceous material. Air is necessary for running the battery and allows having a very light battery, which is essential for the automotive industry. Another important advantage is the low cost of the materials used for manufacturing the battery: the selected metal, carbon support electrode and potassium hydroxide as electrolyte. All these materials are recyclable. A proof-of-concept metal/air cell is manufactured and tested in the project. In addition, the battery concept is validated for automotive application.

The consortium is composed of 8 partners (3 IND, 2 Universities and 3 RTD) covering the complete value chain: battery manufacturer, nanomaterials development (i.e.; nanocatalys, additives and support materials such as carbon), modeling and simulation for cells and batteries design, scaling-up, safety and risks studies for batteries.

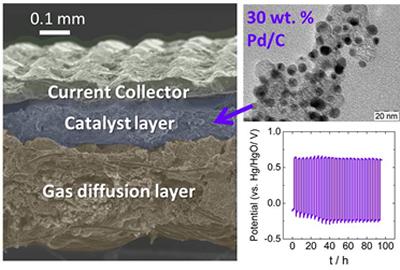

Scanning electrode microscope cross-section of 30 wt. % Pd/C gas diffusion electrode (left) and TEM micrographs for the 30 wt. % Pd/C catalyst used for the gas diffusion electrode (top right) and charge/discharge profiles of Pd/C gas diffusion electrode.

H.A Figueredo Rodriguez, R. Mckerracher, C. Ponce de Leon Albarran, F.C. Walsh. Current distribution in a rectangular flow channel manufactured by 3D-printing. AIChE Journal 63(3) (2017) 1144- 1151 (doi:10.1002/aic.15454).

R.D. McKerracher, H.A. Figueredo-Rodríguez, C. Ponce de Leόn, C. Alegre, V. Baglio, A.S. Aricò, F.C. Walsh. A high-performance, bifunctional oxygen electrode catalysed with palladium and nickel-iron hexacyanoferrate. Electrochimica Acta Volume 206, 10 July 2016, Pages 127–133.

R. McKerracher, C. Alegre, V. Baglio, A.S. Arico, C. Ponce de Leon, F. Mornaghini, M. Rodlert, F.C. Walsh. A nanostructured bifunctional Pd/C gas-diffusion electrode for metal-air batteries. Electrochimica Acta, 174 (2015) 508-515.

R.D. McKerracher, C. Ponce de Leon, R.G.A. Wills, A.A. Shah, F.C. Walsh, “A review of the iron-air secondary battery for energy storage”, ChemPlusChem, Volume 80, Issue 2, February 2015, Pages: 323–335.

C. Ponce de Leon, W. Hussey, F. Frazao, D. Jones, E. Ruggeri, S. Tzortzatos, R.D. McKerracher, S. Yang, R.G.A. Wills, F.C. Walsh, “The 3D printing of a polymeric electrochemical cell body and its characterisation”. Chemical Engineering Transactions, 41, (2014), 1-6.

http://www.green-cars-initiative.eu/projects/necobaut