Policy Projects

Find out more about research projects Public Policy|Southampton are currently working with.

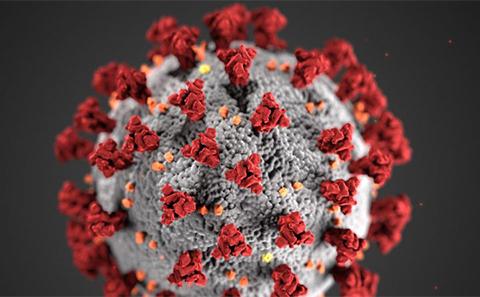

Keeping our healthcare workers safe

Our frontline medical staff are in constant danger of being exposed to COVID-19 infection. The risk of more serious illness is higher for people exposed to a high ‘viral load’, like our doctors and nurses. In Italy an estimated 20% of healthcare workers responding to the COVID-19 outbreak have become infected, and make up 9% of the country’s cases. It is essential that we minimise the risk of infection in medical staff and stop them getting sick at the peak of the pandemic so that they can care for others. Our healthcare workers are using disposable surgical and FFP3 masks which are in high demand, and in many parts of the world are simply unavailable. Many staff have also reported difficulties with how they fit. Personal respirators are an alternative. They use a fan to draw in air, through a filter, and deliver it to an enclosed hood or face mask. However most respirator products are unavailable, and are expensive or heavy, noisy, and uncomfortable.

How to make PeRSo available to as many people as possible?

The prototype design has been published as an open specification (link below) so it is available to other manufacturers around the world. We have launched the PeRSo-DW (Developing World), and will be starting to provide open source modifications for components available to low resource countries. Please click here to go the PeRSo-DW page.

Paul Elkington, Professor of Respiratory Medicine at the University of Southampton, said “It is really important to minimise the risk of infection in medical staff and stop them getting sick at the peak of the pandemic, so that they can care for others. Our next tests will further refine the comfort of the headset and evaluate how it improves efficiency”.

Robert Read, Professor of Infectious Diseases and Director of the Biomedical Research Centre said “PeRSO has been developed by the National Institute for Health Research Southampton Biomedical Research Centre, the University of Southampton and University Hospital Southampton NHS Foundation Trust. Research is the only exit strategy for this pandemic and the Biomedical Research Centre is supporting our Southampton investigators to develop and apply new strategies to help the NHS, enabling collaboration nationally contributing to the national response to COVID-19 ”.

Hywel Morgan, Professor of Bioelectronics at the University of Southampton said “This is an excellent example of industry, universities and hospitals combining their expertise and answering the call to develop solutions needed to save lives in the current crisis".

Recognitions

Southampton Professors Paul Elkington and Hywel Morgan have been awarded MBEs in the Queen’s Birthday Honours for services to medicine and services to biomedical engineering respectively. Read more here.

The Royal Academy of Engineering (RAEng) has awarded the University of Southampton team behind PeRSo - Personal Respirator Southampton - with a President’s Special Award for Pandemic Service for exceptional engineering achievements in tackling COVID-19 throughout the UK. Read more here.

NB: The University cannot accept responsibility for external websites

Watch the three minute briefing with Prof. Paul Elkington and Tom Baynham explaining what makes PeRSo a safe solution for NHS staff.

Watch videoDr Nitin Mahobia presents the key features of the PeRSo ahead of roll out at Southampton General Hospital.

Watch videoThis video demonstrates the preparation, donning, doffing and cleaning protocols for the PeRSo respirator.

Watch videoA look at a prototype PPE unit for NHS workers treating coronavirus patients, developed by the University of Southampton.

Watch videoNew PPE in development at University of Southampton for frontline healthcare staff.

Watch videoThe University cannot accept responsibility for external websites.

We would like to acknowledge the contributions of the following individuals and organisations:

University of Southampton team: Antonio de Grazia, Alex Dickinson, Paul Elkington, Ric Gillams, Alex Mant, Mark Mavrogordato, Roel Mingels, Hywel Morgan, Sebastian Rosini, Constantinos Regas and Dan Spencer.

National Oceanography Centre (NOC): NOC engineers, including Matt Mowlem.

McLaren: Matt Wells, Steve Foster and Scott Bain.

Kemp Sails: Rob Kemp and team.

And in collaboration with the Wessex Academic Health Science Network.

INDO (on behalf of Baynhams) as of the 31st of March 2020 https://www.baynhams.com/covid-19

The University is not manufacturing or supplying PeRSo directly. Our manufacturer, INDO (on behalf of Baynhams), has taken forward product development, safety and resilience testing together with the necessary quality assurance. They scaled up production and delivered PeRSo respirators (under the name of PeRSo 3) to over 20 HHS trusts from Isle of Wight to Scotland after receiving regulatory approval.

PeRSo is not a novel product; however it uses off-the-shelf components, which may help to avoid current global supply challenges for PRE.

Equipment such as FFP3/N95 masks may fail during use because the seal between the skin and the mask leaks during talking or after prolonged use, with a failure rate reported at approximately 20%. Furthermore, they give no eye protection. The PeRSo is a reusable battery-powered system that HEPA filters the air, removing 99.95% of particulate matter. The HEPA is held within a moulded housing and so cannot leak; and air is circulated via a fan. The hood provides splash protection and stops you accidentally touching your face, which is a common route of infection. Moreover, the large transparent visor allows patients to see healthcare workers’ face.

University of Southampton researchers have performed the standard aerosol testing used for face fit testing, and the PeRSo passed the test even when the spray was fired recurrently into the HEPA filter. Similarly, we have performed a smoke test, with smoke blown at the head, and no penetration occurred. The manufacturing partners are undertaking their own product validation and testing before making products available.

The prototype, now renamed PeRSo 1 by INDO, has not been fully certified just yet, but they are working to ensure their product conforms with the relevant standards (for the UK market this is BS EN 12941:1998+A2:2008, under the PPE Regulation). However, PeRSo 1 is completing CE certification and is expected to be available for sale by the end of January.

PeRSo 3 is certified for BS EN 12941:1998+A2:2008.

The University isn’t looking for trial participants or trial sites. The manufacturing partners will be taking forward their own quality assurance and testing. If the situation changes we will update this page.

Battery life after one charge is 12 hours for PeRSo 1, and up to 8 hours for PeRSo 3.

10,000 PeRSo units per week can be delivered by Baynhams.

The prototype for PeRSo was built from existing and available components. The manufacturing partners redesigned some elements and sourced or manufactured components to hit production scale. Price of finished products can be found on the Baynhams website.

Yes, you can find the products on the Baynhams website.

Prototypes have been tested by respiratory physicians and nurses. The doctors primarily commented on the advantage of not needing to change PPE frequently, which makes work much more efficient, and the protection given when on wards where FFP3 face masks are not used, such as COVID19 unknown wards. One nurse, who had worked during the SARS epidemic, commented that the flow of air down the face was much more comfortable than a FFP3 mask for long term use.

If given further support, we would like to develop variations, such as the PeRSo-DW (Developing world, made from widely available materials as low cost as possible) and PeRSo-GP (front mounted so that it can be used during seated consultations).

Please complete our webform. We would be interested to hear from businesses in the UK and internationally.

Please contact the Media Relations Team at press@soton.ac.uk.

Except as represented here the Specification for the PeRSo Prototype and any information provided on this website and linked pages is provided “AS IS”. The University of Southampton gives no assurance, guarantee or warranty, express or implied, that any PeRSo device manufactured or assembled following this specification: will be safe to use; will be of merchantable quality; will be fit for any particular purpose; will protect individuals from contracting Covid19 or any other infectious disease or virus whilst using it; or that individuals using it will not suffer personal injury or death. The University of Southampton does not warrant or in any way assert that the manufacture, sale or use of PeRSos will not infringe the intellectual property of any other person or organization. The University of Southampton hereby disclaims any and all warranties, express or implied, and excludes, to the maximum extent permitted by law, any and all liability for any loss, harm, damage, injury or death suffered by any person caused by, or resulting from, their reliance on the information, designs and Specifications provided.

Find out more about research projects Public Policy|Southampton are currently working with.

Follow the news and opportunities related to Covid-19 and discover how PPS support UoS academics sharing their knowledge and expertise whenever there is a request from policymakers.