Developing a new sensor system to assess lower limb prosthetics

Key details of this case study:

Summary: Our novel body interface sensor system addresses challenges in lower limb prosthetics and helps to prevent pain for amputees

Status: Completed

Key staff: Professor Liudi Jiang, Professor Dan Bader

This is a tremendously exciting project which has the potential to transform socket technology as a whole in lower limb prosthetics.

Explore this case study:

The challenge

Many lower limb amputees experience extensive and prolonged forces at their stump or socket interface whilst walking, which can lead to discomfort and pain.

The socket represents one of the most critical components in lower limb prosthesis. Yet to date, objective assessment of socket fit is largely unknown due to the current unavailability of a multidirectional force sensor system which could be applied at the residuum/socket interface. In collaboration with Chas. A. Blatchford & Sons Ltd, University of Southampton researchers aimed to address this unmet need.

What we did

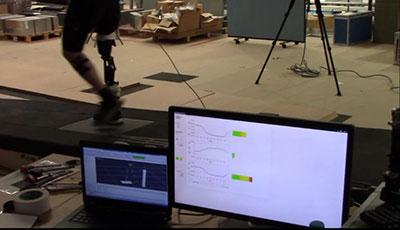

Our research team has developed a novel body interface sensor system which can be applied at the residuum/socket interface, and measure multidirectional pressure and shear in real time. Preliminary studies with lower limb amputees have been very successful.

The research has generated new understanding in the interdisciplinary fields of medical, engineering and physics, and the sensor is also applicable to a wide range of biomedical application areas associated with the designs of insoles, mattresses, special seating, assistive rehabilitation robotics, and orthotics.

This research project received funding from The Medical Research Council.

Our impact

This novel sensor system has the potential to provide objective assessment of socket fit and early detection of sores, helping prevent any pain and discomfort experienced by amputees using lower limb prosthesis.

As well as generating new biomechanical understanding, our collaborative research has led to many prizes including Best Free Paper BLESMA Prize 2015, the Limbless Association Prize 2014, and Best Paper Prize for Advancing Technology at ISPO World Congress 2017.

The interdisciplinary nature of the work has led to many journal papers, one of which, in Medical Engineering and Physics, won the prestigious 2015 Institute of Engineering and Technology William James Award.

Further research is currently underway to translate this sensor innovation to clinically-applicable tools, effectively assisting amputee care and rehabilitation.

The facilities we used

We used the following facilities within the University - Engineering Material lab and Testing and Structures Research Laboratory

Find out more about the Engineering and Environment Faculty's many world class facilities.

Partners we worked with

This research was an interdisciplinary collaboration between Engineering and Health Sciences within the University of Southampton.

We also worked closely with an external partner in the form of UK company Chas. A. Blatchford & Sons Ltd (prosthetics and orthotics).

Awards received for this research

- Winner of the Limbless Association Prize 2014

- Winner of William James Prize 2015

- Winner of British Limbless Ex-Serviceman’s Association (BLESMA) Prize 2015

- Winner of the Best Paper Prize for Advancing Technology at ISPO World Congress 2017

Related Staff Member

Related Staff Member

Links to external websites

- TRIPS sensor system

- BBC News - Pressure sensors to help prevent pain for amputees

- Watch a Forces TV video about this research

- Blatchford prosthetics

The University cannot accept responsibility for external websites.

Other University of Southampton sites

You might also be interested in

Engineering Materials Research Group

Discover more about our related research group, dedicated to developing understanding of materials that affect the performance of engineering systems.

Other healthcare and medicine case studies

Learn more about the research we are undertaking in these areas.

Postgraduate Opportunities

Explore our postgraduate research degrees.

Media Enquiries

Make a media enquiry about this case study