Carlos Ponce de León, Frank C. Walsh

Electrochemical Engineering Laboratory, Energy Technology Group, Faculty of Engineering and the Environment, University of Southampton

Background

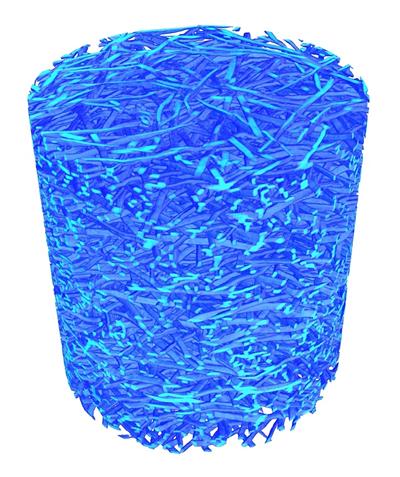

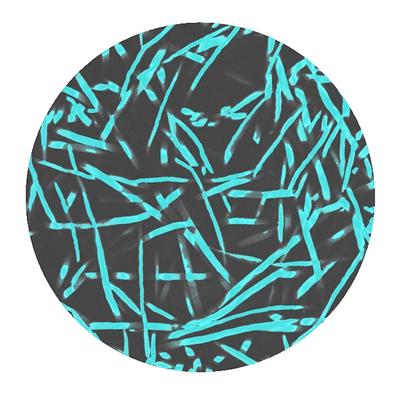

Titanium felt is a rigid porous material commonly used as a highly effective electrode material. As such, it has been applied successfully in electrochemical flow reactors for hypochlorite production, cerium-based redox flow batteries and reversible unitized fuel cells. Its large surface area enables increasing the limiting current and space-time yield of the electrode reactions as well as reducing mass transport limitations. Morphological and structural analysis of these type of materials are usually performed in order to assess their mechanical properties, thermal and electrical conductivities and their hydraulic permeability.

Role of Computed Tomography

In this case, CT has been employed to evaluate the structure and porosity of several samples of titanium felt. High resolution CT images have revealed the random orientation of the individual titanium fibres along the plane X; a consequence of the manufacturing process. Such arrangement results in anisotropy in the overall porous material in terms of electrical and thermal conductivity as well as hydraulic permeability. Furthermore, it was observed that the fused individual fibres have rectangular-like cross sectional areas. An estimation of the volumetric porosity yielded 0.76, which is in agreement with gravimetrical measurements. The obtained data will permit to predict the properties of the reaction environment in electrochemical flow reactors using this type of electrode materials.

Acknowledgements

The authors would like to acknowledge the support provided by CONACYT and SEP and the assistance of Dr. R. P. Boardman. Additional materials were supplied by RIFI (University of Southampton).

Figure 1 - CT scan of a cylindrical titanium felt sample. Diameter 2.4 mm. The individual fibres lie predominantly in horizontal position, resulting in anisotropy.

Figure 2 - Cross section of a cylindrical titanium felt sample obtained via CT. Diameter 2.4 mm. The random distribution of the individual fibres in the porous matrix can be observed.