Federico Romei, Dr Angelo N. Grubišić

Faculty of Engineering and the Environment, Astronautics Research Group, University of Southampton

Introduction

The objective of the current research is to develop a next generation electrothermal thruster that can increase the capability of small spacecraft, whilst enabling the first fully all-electric propulsion system architecture on larger spacecraft, which utilises a large primary electric propulsion system.

Resistojet propulsion systems for spacecraft consist of an electrical heat exchanger that increases the enthalpy of a propellant, which is accelerated through a nozzle to produce thrust. The performance of this electrothermal thruster increases proportionally to the square root of the gas temperature. Increasing the propellant temperature of the thruster also decreases the amount of propellant required on board of the spacecraft to accomplish a specific mission.

This research programme includes design, electrothermal simulations, manufacturing, performance testing and ultimately the validation of a Very High Temperature Resistojet (VHTR) development model thruster. Metal additive manufacturing, and in particular Selective Laser Melting (SLM), has been selected to enable the build of a complex thin-wall heat exchanger as a single element. However, due to the complexity of the design and SLM manufacturing limits, a comprehensive and focused materials and manufacturing verification process study was necessary.

Description of specimen

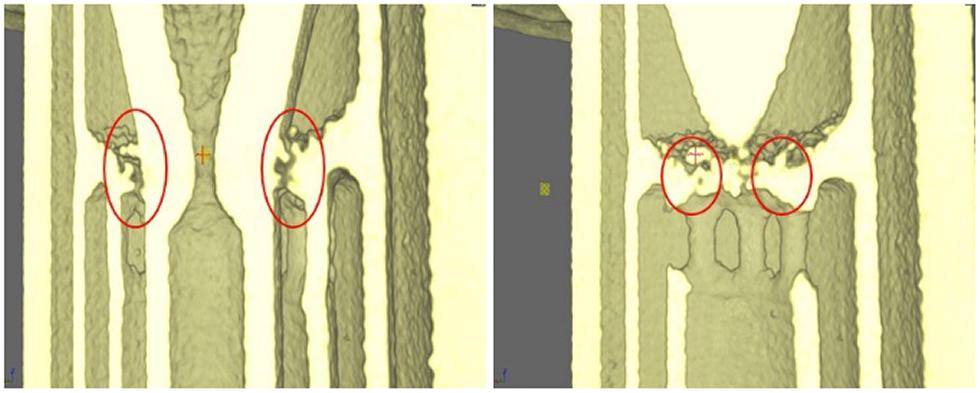

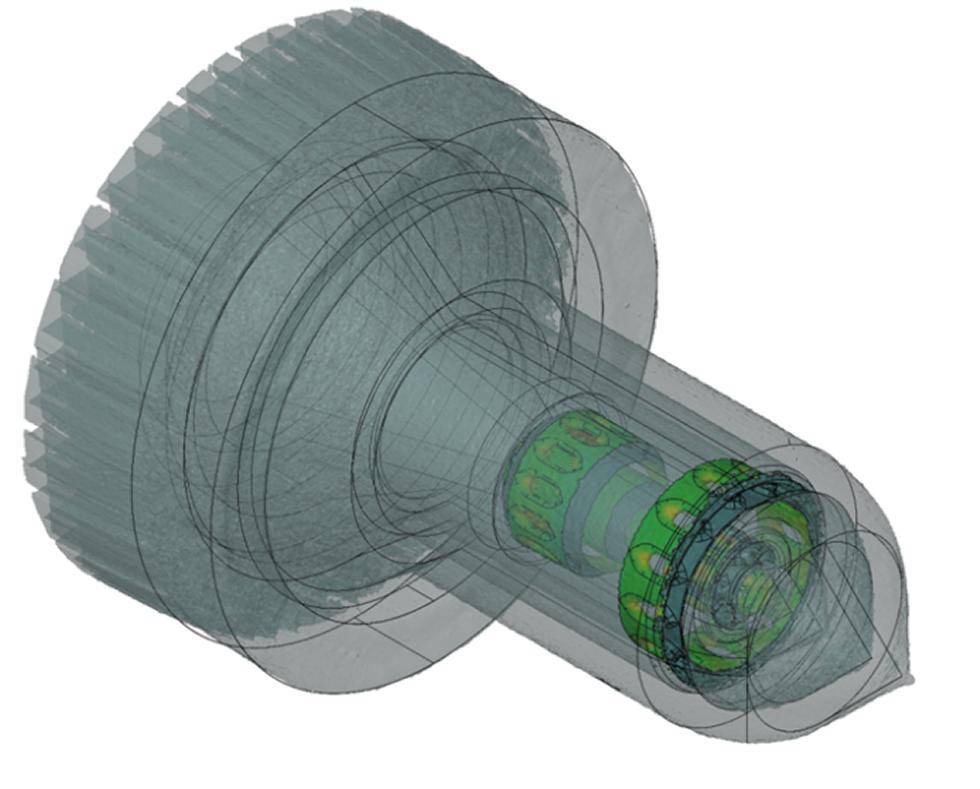

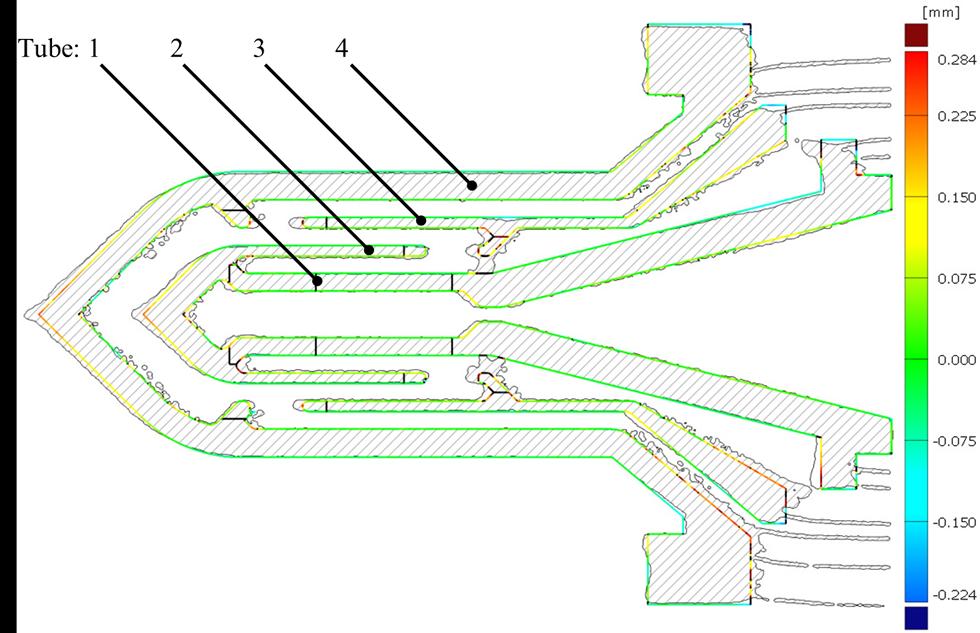

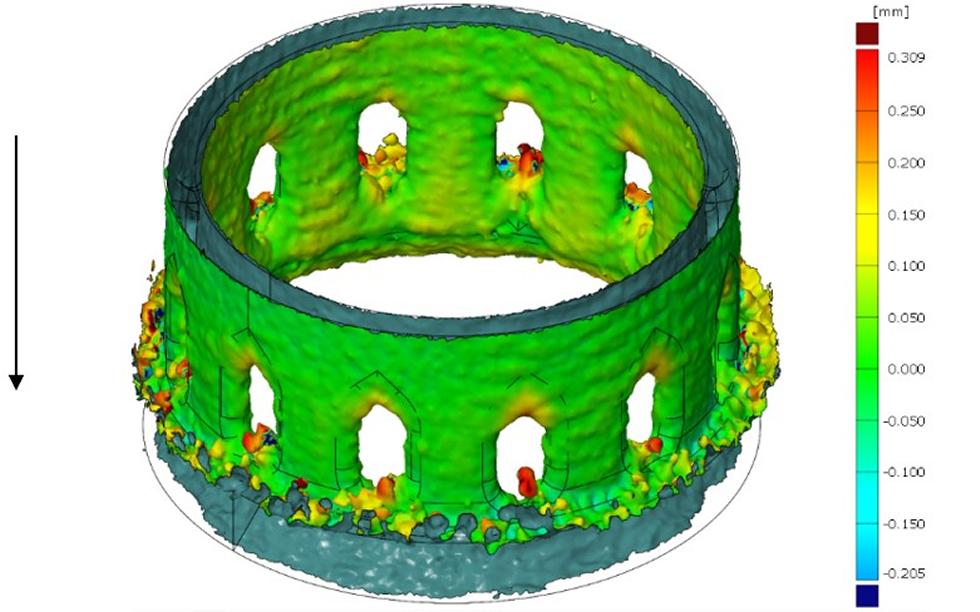

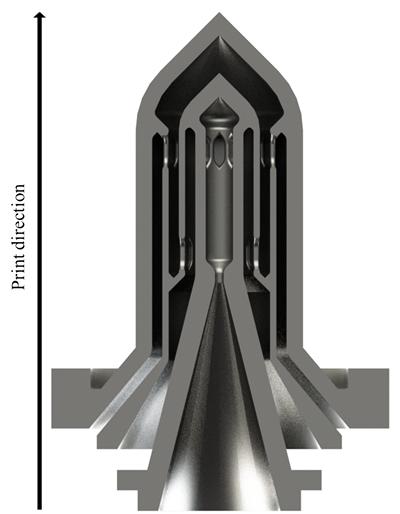

The specimen analysed is a monolithic 316L heat exchanger manufactured by SLM with a Concept Laser M2 3D metal printer at the EDMC. It consists of four thin-wall concentric tubes converging into a conic nozzle. The wall thickness from the innermost is 500 μm, 300 μm, 300 μm and 800 μm.

Role of X-ray Computed Tomography

High-resolution micro-Computed Tomography (CT) is used as a tool for non-destructive inspection, since the complex geometry of the thruster does not allow internal examination. The CT volume data is used to determine a surface mesh to perform coordinate measurement, nominal/actual comparison and wall thickness analysis.

Setup

System used: Modified 225 kVp Nikon/Xtek HMX

Sample setup: Vertically, with the nozzle facing down (Figure 1 - top right on this page).

Outputs

- Romei, F., A. N. Grubišić, and D. Gibbon. "Manufacturing of a high-temperature resistojet heat exchanger by selective laser melting." Acta Astronautica (2017).

- conference paper: Romei et al., “Selective Laser Melting for Production of a Novel High Temperature Electrothermal Propulsion System”, 67th International Astronautical Congress (IAC), Guadalajara, Mexico, 26-30 September 2016.